Crane Slewing Bearing: Key Technologies, Advantages and Applications

About Author: Iker Heras Miguel

A researcher in the Department of Mechanical Engineering at the University of the Basque Country (UPV/EHU), Spain, he specializes in the modeling and design of slewing bearings. His research interests include friction torque prediction, load distribution analysis, and the mechanisms affecting ring stiffness. His findings are widely used in the mechanical design of wind power, lifting equipment, and large structures.

In the field of modern lifting and heavy machinery, crane slew bearing is one of the core components that determine the efficiency and safety of equipment operation. As a key hub connecting the upper structure and the lower structure, it undertakes multiple functions such as rotation, bearing and positioning, and is the basis for the crane to achieve precise rotation and smooth operation. Whether in tower cranes, crawler cranes, or port handling equipment, the performance of slewing ring directly affects the stability and service life of the whole machine.

Therefore, an in-depth understanding of the structural characteristics, classification methods and core technologies of crane slew bearing is of great significance to mechanical engineers, equipment manufacturers and maintenance personnel. This paper will systematically introduce the technical characteristics and advantages of different types of slewing bearings, and analyze their application in construction, port logistics, metallurgical mines and marine engineering.

Structural characteristics and classification of crane slewing bearing:

In my opinion, to understand the crane slewing ring, we must first start with its “skeleton” and “mode of operation.

Basic composition and working principle:

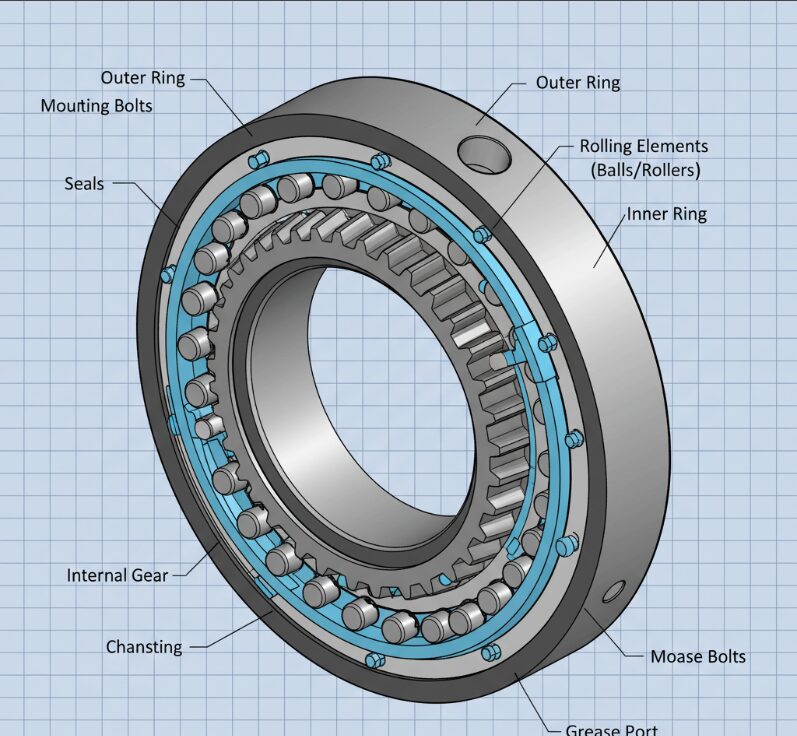

When it comes to slewing bearings, I always compare them to a precise and sturdy “ring hub”. Its core composition is actually not complicated: it usually includes two inner and outer rings, which are the basis of bearing; between these two rings, it is what we often call rolling elements-it can be steel balls or cylindrical rollers. They are the key to achieving relative movement; in order to keep the rolling bodies at a proper distance, we will use spacers, sometimes more complicated cages; of course, the external sealing device is to prevent dust and debris from entering and grease loss, and the grease nipple is the entrance for regular maintenance.

Its working principle is that through these rolling elements, the upper structure of the crane (such as boom, cab) can rotate smoothly around the lower structure (chassis, legs). At the same time, more importantly, it must also bear complex loads from multiple directions at the same time, including axial forces in the vertical direction, radial forces in the horizontal direction, and the most critical overturning moment. In engineering terms, it is “multi-directional load, single-point rotation”.

Common types and their technical characteristics:

In practical application, the type of slewing bearing is selected according to the specific working conditions and carrying requirements of the crane. There is no “best”, only “best fit”.

- Single row four point contact ball slewing ring:

- Features: This is 1 very “all-round” type, relatively compact structure and light weight.

- Advantages: Its advantage is that it can bear axial force, radial force and overturning moment in a relatively balanced manner, and has a wide range of applications.

- Application example: it is often used in some small and medium-sized cranes, such as small crawler crane, truck crane rotating mechanism, very handy.

- Double row reducing diameter ball type slewing bearing:

- Features: It has two rows of steel balls of different diameters, which makes its carrying capacity, especially the ability to resist overturning moment, have been significantly improved.

- Advantages: It is a very reliable choice in the pursuit of high stability and long life.

- Application example: medium and large port cranes and tower cranes, which need to face large wind loads and operating radius of equipment, are basically inseparable from it.

- Three rows of cylindrical roller slewing bearing:

- Features: Its carrying capacity is the strongest of all types, and its rigidity is very good.

- Pros: Its performance is overwhelming in the face of extra large tonnage and high impact loads.

- Application examples: heavy lifting equipment like port portal cranes, metallurgical cranes and offshore platforms, these are the places where it is used.

- Ball column joint type slewing bearing:

- Features: This type is relatively special, it cleverly combines the advantages of steel balls and rollers.

- Advantages: Its design philosophy is to achieve the optimal comprehensive performance in a specific application, not only to consider the load, but also to take into account certain speed requirements.

- Application example: frankly speaking, this kind of heavy equipment appears more in some special working conditions, and needs to be customized according to specific needs.

Effect of materials and manufacturing processes on performance:

In my opinion, the performance of slewing bearing is not only the difference in design, but also the key to its “vitality.

- Material selection: We usually choose high-strength alloy steel, such as 42CrMo. But the material itself is not enough, the heat treatment process is the key. Through quenching and tempering, we can precisely control the hardness and toughness of the raceway to ensure that it has sufficient wear resistance to resist the long-term wear of the rolling elements and sufficient fatigue strength to withstand periodic loads.

- Machining accuracy: This is an extremely detailed link, but it is directly related to the bearing capacity and service life of the slewing bearing. The depth of the raceway hardening layer must be uniform and meet the design requirements, too deep or too shallow will affect performance. The grinding accuracy, especially the geometric shape accuracy and surface roughness of the raceway, determines the smoothness of the rolling body movement and the uniformity of the load distribution. If the accuracy is not enough, you will find that the equipment has abnormal noise during operation, and even premature wear and fatigue failure. After all, no matter how good the design is, no precision manufacturing process is just a castle in the air.

Core performance advantages of crane slewing bearings

Excellent carrying capacity and stability

I often compare the slewing ring to the “joint” of the crane, it must be strong enough to withstand a variety of complex loads. Its most significant advantage is the ability to withstand multi-directional loads. This means that no matter how the boom is extended and the load changes, the slewing bearing can simultaneously withstand huge axial forces (vertical pressure), radial forces (horizontal push and pull) and the critical overturning moment (the force trying to tip the equipment over). This multi-dimensional carrying capacity is the cornerstone of the overall stability of the lifting equipment, without it, any heavy lifting operation will be a castle in the air.

At the same time, the high rigidity design of the slewing bearing is also very important. I have seen many poorly designed bearings, which will produce obvious deformation under heavy load, which directly affects the lifting accuracy and operation safety. The excellent slewing bearing, its structural design can ensure that under the huge load still maintain a very low deformation, so as to ensure the accuracy of the boom positioning. This is what I value most at the scene, because even a small deformation may lead to serious consequences.

Accurate rotation accuracy and smoothness

Smooth rotation is important for operational efficiency and safety. The precise rotation accuracy and stability of the slewing bearing make a great contribution in this respect. Its internal rolling body design can effectively reduce friction and energy loss. I have compared the slewing bearings of different brands. Those rolling elements with more reasonable design can indeed significantly reduce the rotation resistance, which not only improves the transmission efficiency, but also reduces the energy consumption. In the long run, it can save a lot of operating costs for enterprises.

In addition, low noise and vibration are also important indicators for me to measure the pros and cons of a slewing bearing. Precise processing technology and reasonable gap design are the key to achieve this. When the crane is working, if the slewing bearing makes a harsh noise or produces obvious vibration, it not only affects the comfort of the operator, but also indicates potential mechanical problems. Excellent support, its operation should be quiet and smooth, which reflects its inherent workmanship.

Excellent wear resistance with long life

The life of the equipment is directly related to the return on investment. At this point, the excellent wear resistance and long life of the rotary bearing are my first considerations when choosing. Heat treatment processes are key to extending their life. The quenched and hardened layer on the raceway surface is like putting a hard layer of armor on the bearing, effectively resisting wear and tear in daily operation.

And sealing technology is an effective means to protect the inside “heart” from the outside world. Multiple lip seal or labyrinth seal structures are effective in preventing the intrusion of dust, moisture and foreign matter. In the dusty, humid and changeable environment of a construction site, if the sealing is not good, the grease will soon fail and the rolling element will wear faster as a result. Therefore, a reliable sealing system is a necessary condition to ensure the long-term stable operation of the rotary bearing.

Of course, no good piece of equipment can be separated from maintenance. The importance of lubrication maintenance cannot be overemphasized. Regular and correct filling of grease can keep the slewing bearing in optimal working condition. It’s like a car needs regular maintenance, lubricated in place, naturally less wear and longer life.

Ability to adapt to harsh conditions

Cranes often need to work in a variety of extreme environments, which requires the ability to adapt to harsh working conditions. For example, in the cold north or hot desert areas, high temperature/low temperature resistance is particularly important. Special alloy materials and high-performance grease are the key to ensure its normal operation under extreme temperatures. I once participated in the equipment selection of a polar project, and the requirements for the low temperature resistance of the support were very strict.

In addition, anti-corrosion design for offshore platforms and chemical enterprises is also essential. In these corrosive environments, the surface treatment and protective measures of the slewing bearing must meet the highest standards to resist salt spray, chemical corrosion and other erosion, to ensure the long-term reliability of the equipment. This is an often overlooked but crucial detail.

Modular design and ease of maintenance

In equipment management, modular design and ease of maintenance can significantly reduce operating costs and downtime. The standardization and interchangeability of slewing bearings make it easy to replace parts. If a component is damaged, we can quickly find a replacement for replacement, instead of scrapping the entire support, which undoubtedly improves the utilization rate of the equipment.

Finally, although the grease nipple design is a small detail, it can reflect the user-friendliness of the design. Convenient and quick grease filling can reduce the workload of maintenance personnel, shorten downtime, and ensure that equipment can be put into production faster. This is an advantage that cannot be ignored in the pursuit of efficiency today.

Wide application field of crane slewing bearing

The application range of slewing bearings is very wide, covering almost all heavy machinery fields that need to rotate and carry.

Construction Engineering Field

When I first saw dozens of stories rise, I knew that tower cranes played a key role. Every time it rotates, it is inseparable from the slewing bearing at the bottom. Similarly, on those rugged construction sites, crawler cranes and truck cranes flexibly lift heavy components.

Whether it is bridge construction or high-rise building construction, slewing bearings ensure that these behemoths can be accurately positioned and operated efficiently. This is the most direct test of bearing capacity and rotation accuracy.

Port and Logistics Field

Portal cranes, container cranes and even floating cranes require frequent and precise slewing for cargo handling and container transfer. In the face of massive cargo and huge throughput, slewing bearings must have high load capacity and excellent fatigue resistance. I often think about how such parts can remain stable under sea wind erosion and heavy load impact. Behind this is the perfect combination of material science and structural design.

Metallurgy and Mining Field

In the environment of high temperature, heavy load and dust, the slewing bearing should not only ensure the stable operation of the equipment, but also bear the huge impact load. The slewing bearing design here takes more into account wear resistance and reliability to ensure that the equipment can continue to work under extreme conditions.

Ocean Engineering and Wind Power.

This is one of the most technically challenging areas. Offshore lifting platforms and offshore engineering ships are used for oil and gas extraction and equipment installation on rough seas, which puts forward extremely high requirements for the anti-corrosion and anti-fatigue performance of slewing bearings. Although wind turbines, especially their yaw and pitch bearings, are different from traditional “crane slewing bearings” in classification, they emphasize precise rotation and positioning in a specific plane in terms of technical principles and performance requirements, and have almost stringent requirements for life and reliability.

Conclusion:

Crane Slew Bearing is not only the “rotary joint” of cranes, but also the technical core of their stability and reliability. With excellent multi-directional bearing capacity, high-precision rotation performance, excellent wear resistance and long life characteristics, Slewing Ring has shown irreplaceable value in modern construction machinery.

With the increasing demand for intelligence, heavy load and high reliability, future Crane Bearing Manufacturer will pay more attention to material innovation, heat treatment process optimization and modular design to achieve higher load efficiency and maintenance convenience. From the construction site of high-rise buildings, to port logistics, metallurgical equipment and offshore wind power platforms, Crane Slew Bearing will play a key role in driving the global upgrade of heavy equipment technology.

SWBTEC

SWBTEC